Fireblock

The passive fire protection has an increasing importance to minimize the damage in the event of fire in platforms, refinery, petrochemical plant, thermal powerPlant, ship building and wherever actuators, valves, counters and electronic control systems for fluids and gases in explosive ambientare installed. The new product line Fire-Block” is designed to guarantee the protection of components in case of fire. Our material layering are tested and certified according to UL 1709.

NISSI OIL & GAS EQUIPMENT TRADING LLC ;

Fireblock

Type Approval Certificate for Enclosure systems tested according to Norm UL 1709

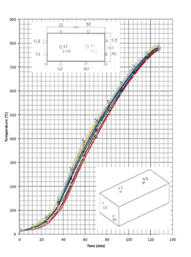

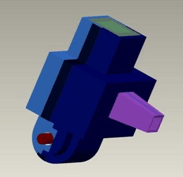

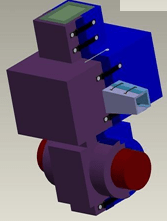

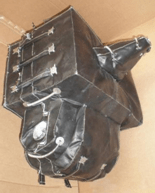

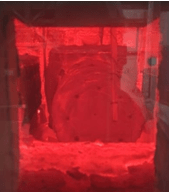

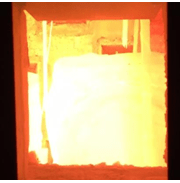

Pictures from one of our test campaigns: “Fire Block” jacket system tested under Hydrocarbon Pool Fire scenario UL1709, over several geometries and massivities, faithfully representing the equipments to be protected.

During the test

PassiveFireProtection-UL1709

Type Approval Certificate for Enclosure systems tested according to Norm UL 1709

Successful results from test campaigns: test units are selected to cover a wide range of equipments, by the mean of a proper combination of the parameters “geometry–massivity”

Layering of the jackets, nature of material, thickness, and design in general for the desired firerate, are conceived under the consideration of the critical temperatures of the equipments to protect (e.g.actuators), being +70 to +110°C