Fabric Expansion Joint

Enhance Industrial Efficiency with Fabric Expansion Joints in UAE

Fabric Expansion Joints: Absorbing Movement and Dampening Noise in Your Ductwork Systems

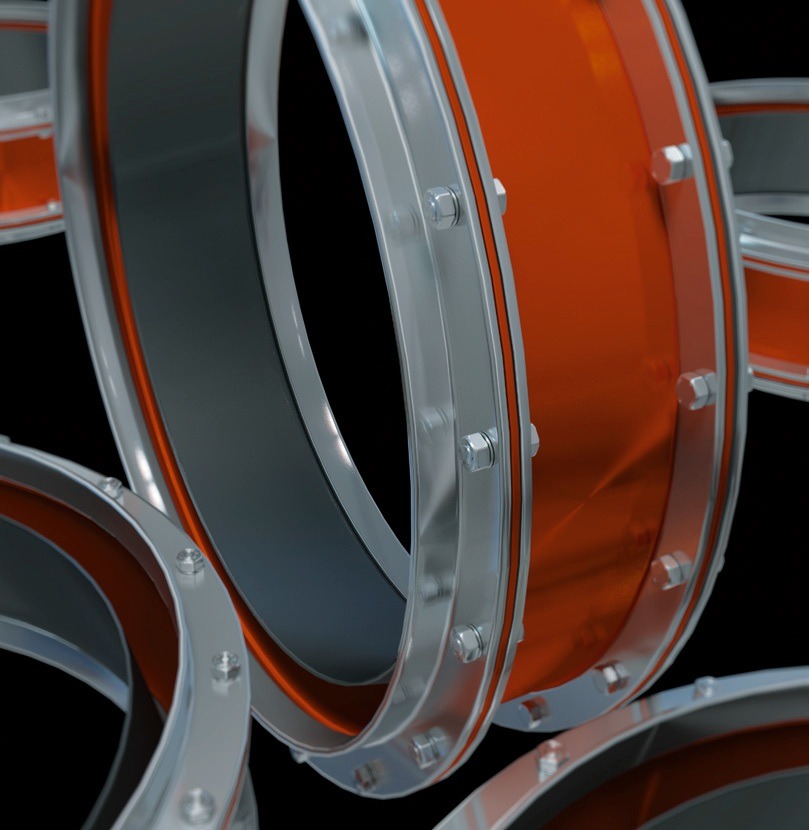

In the world of industrial airflow, maintaining consistent and efficient operation hinges on managing movement and vibration. Enter fabric expansion joints, the workhorses of ductwork flexibility.

This guide dives deep into fabric expansion joints, exploring their applications, functionalities, and the nitty-gritty details like material selection and attachment methods. By the end, you’ll be equipped to identify the perfect fabric expansion joint for your specific needs.

Understanding Fabric Expansion Joints

Fabric expansion joints, also known as duct expansion joints or fabric bellows, are strategically placed within ductwork systems to address several key challenges:

- Thermal Expansion and Contraction: As temperatures fluctuate, metal ducts expand and contract. Fabric joints accommodate this movement, preventing stress on ductwork and connections.

- Vibration Isolation: Industrial fans and blowers can generate significant vibrations. Fabric joints act as shock absorbers, dampening these vibrations and protecting connected equipment.

- Misalignment: Even the most meticulously planned ductwork installations can experience slight misalignments. Fabric joints provide flexibility to compensate for these misalignments, ensuring a proper seal and optimal airflow.

These advantages make fabric expansion joints essential components in various industries, including:

- Power Generation

- Petrochemical Processing

- Pulp & Paper Manufacturing

- General Industrial Facilities

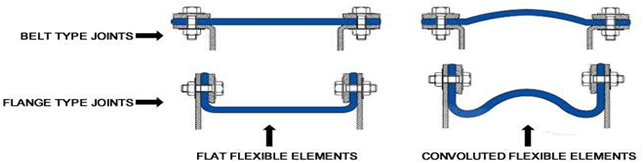

Unveiling the Fabric Belt Design

The core of a fabric expansion joint lies in its namesake – the fabric belt. This flexible element, typically flat in design, offers several advantages:

Versatility: Fabric belts can be paired with various frame types to suit diverse operating conditions.

Effective Manufacturing & Installation: Flat belts are easier to produce and install compared to more complex designs.

Compatibility: They can accommodate a wide range of frame configurations.

Unveiling the Fabric Belt Design

Material Matters: Choosing the Right Fabric

FABRIC BELT EXPANSION JOINT

FLUOROPOLYMER

FABRIC BELT EXPANSION JOINT• COMPOSITE

FULLY MOLDED DUCT EXPANSION JOINT

Beyond the Fabric: Exploring Frame Options

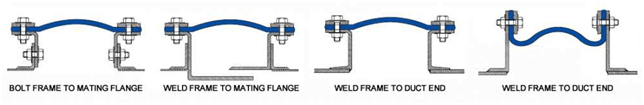

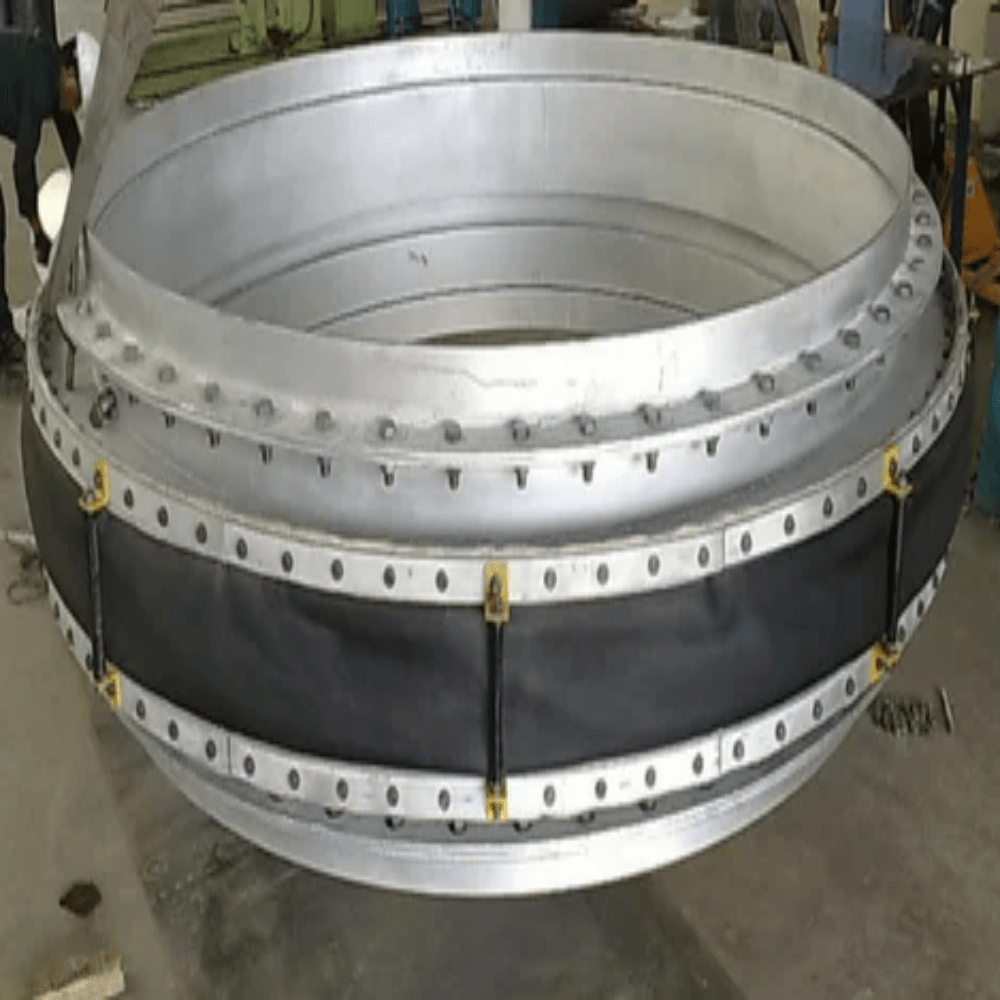

Fabric belts work in conjunction with frames, providing a sturdy structure and connection points for ductwork attachment. Here are some common frame types:

- Bolt Frames: These frames are bolted to mating flanges on the ductwork, offering a secure and easy-to-disassemble connection.

- Weld Frames: Permanently welded to the ductwork flanges, these frames provide a strong and leak-proof connection.

The choice of frame material typically aligns with the ductwork material, such as galvanized steel for compatibility.

Putting it All Together: Attachment Methods

The way a fabric expansion joint attaches to the ductwork is vital for overall system integrity. Here are the most common attachment methods:

- Bolt Frames to Mating Flange: The bolt frame is secured to pre-existing flanges on the duct ends using bolts and gaskets.

- Weld Frames to Mating Flange: The weld frame is directly welded to the ductwork flanges, creating a permanent and leak-proof connection.

- Weld Frames to Duct End: Similar to the above, the weld frame is welded directly to the duct ends themselves.

Beyond the Basics: Additional Considerations

While the core functionalities are covered, several other aspects can influence your fabric expansion joint selection:

- Baffles and Liners: In some cases, baffles or liners made of fabric or metal are incorporated within the joint to protect the fabric element from abrasion or improve airflow.

- Insulation Pillows: For applications requiring thermal insulation, insulation pillows can be integrated within the joint.

Face-to-Face Width: This refers to the distance between the two connecting flanges of the joint. Allowable movement capabilities often vary depending on the face-to-face width.

Conclusion: Fabric Expansion Joints – A Sound Investment for Optimal Ductwork Performance

Fabric expansion joints offer a compelling value proposition for industrial ductwork systems. Their ability to:

- Absorb thermal expansion and contraction

- Isolate vibration

- Accommodate misalignment

Ensures smooth operation, protects equipment and minimizes downtime. Additionally, the variety of:

- Fabric materials

- Frame options

- Attachment methods

Allows for customization to meet specific application requirements.

By carefully considering factors like:

- Chemical resistance needs

- Temperature limitations

- Abrasion potential

- Pressure requirements

you can select the ideal fabric expansion joint to optimize your ductwork system’s performance and lifespan.

Beyond Functionality: The Benefits of Informed Selection

Choosing the right fabric expansion joint goes beyond just functionality. Here are some additional advantages of making an informed selection:

- Enhanced System Efficiency: Properly designed fabric joints minimize pressure drops within the ductwork, leading to improved airflow and energy savings.

- Reduced Noise Levels: By dampening vibrations, fabric joints contribute to a quieter working environment.

Simplified Maintenance: The modular design of most fabric joints facilitates easier inspection and replacement compared to welded or permanently fixed components.

These advantages make fabric expansion joints essential components in various industries, including:

- Power Generation

- Petrochemical Processing

- Pulp & Paper Manufacturing

- General Industrial Facilities

A Final Note: Partnering for Success

Selecting the most suitable fabric expansion joint requires careful consideration of various factors. Consulting with a reputable manufacturer or distributor can be highly beneficial. Their expertise can guide you through the selection process, ensuring you choose a joint that aligns perfectly with your specific needs and operating conditions.

By leveraging the advantages of fabric expansion joints and making informed choices, you can create a robust, efficient, and long-lasting ductwork system for your industrial application.

Fabric Expansion Joints: A Deep Dive into Specifications and Advanced Applications

Specifying Your Fabric Expansion Joint: Key Parameters

When selecting a fabric expansion joint, several key parameters need to be defined to ensure a proper fit for your ductwork system.

Size: This refers to the duct diameter the joint is designed for. It’s crucial to ensure compatibility with your existing ductwork.

Movement Capability: This specifies the amount of expansion and contraction the joint can accommodate. It should be sufficient to handle the anticipated thermal movement in your system.

Pressure Rating: The joint needs to be rated for the maximum static pressure within the ductwork to prevent leakage or damage.

Temperature Range: The chosen materials must be suitable for the expected operating temperature spectrum of your airflow.

Material Selection: Based on the factors discussed earlier (chemical resistance, abrasion, etc.), identify the most appropriate fabric and frame materials for your application.

Additional Specifications:

Face-to-Face Dimension: As mentioned previously, this is the distance between the connecting flanges. It can impact movement capability and needs to be considered during installation.

Flange Thickness and Material: Ensure compatibility between the joint’s flange thickness and material with your ductwork flanges.

Insulation Requirements: If thermal insulation is necessary, specify the desired insulation thickness and material.

Understanding Movement Capabilities:

Fabric expansion joint movement capabilities are typically denoted in two ways:

Axial Movement: This refers to the amount of expansion and contraction the joint can accommodate along the centerline of the duct.

Lateral Movement: This specifies the ability of the joint to handle slight misalignments between duct sections.

Movement capabilities often vary depending on the face-to-face width and chosen materials. It’s essential to select a joint with sufficient movement capacity to address your specific needs while maintaining optimal system performance.

Advanced Applications: Pushing the Boundaries of Fabric Expansion Joints

Fabric expansion joints aren’t limited to basic ductwork applications. Here are some examples of their use in more demanding scenarios:

- High-Temperature Applications: Specialized fabric joints made with high-temperature resistant materials like silicone-coated fiberglass can handle extremely hot airflow, commonly found in power generation or flue gas exhaust systems.

- Low-Pressure Clean Air Applications: Fabric joints constructed with smooth, non-porous materials are ideal for cleanroom environments or applications involving sensitive materials like pharmaceuticals.

- Acoustic Attenuation: Certain fabric joint designs incorporate acoustic insulation materials to dampen noise transmission within ductwork systems, contributing to a quieter work environment.

- Rectangular Ducts: While most commonly used in circular ducts, fabric joints can be custom-designed for rectangular ductwork configurations as well.

These examples showcase the versatility of fabric expansion joints and their ability to adapt to diverse industrial requirements.

Installation and Maintenance Considerations

While fabric expansion joints are known for their ease of installation compared to other options, proper installation procedures are crucial for optimal performance and longevity. Here are some key points to remember:

- Follow the manufacturer’s installation instructions: Each joint may have specific installation requirements depending on the design and attachment method.

- Ensure proper alignment: The joint needs to be aligned correctly with the ductwork sections to prevent stress and leakage.

- Verify secure attachment: Bolted connections should be tightened to the recommended torque specifications. Welded connections should be performed by qualified personnel.

- Regular inspections: Periodically inspect the fabric element for signs of wear, damage, or excessive movement. Schedule replacements when necessary.

By following these guidelines, you can ensure your fabric expansion joints function optimally throughout their service life.

Conclusion: Fabric Expansion Joints – A Strategic Investment for Industrial Ductwork Systems

Fabric expansion joints represent a strategic investment for industrial ductwork systems. Their ability to manage movement, isolate vibration, and accommodate misalignment translates to:

- Enhanced system efficiency

- Reduced maintenance costs

- Improved safety and reliability

- Quieter work environment

By carefully considering the various factors discussed in this comprehensive guide, you can select the ideal fabric expansion joint for your specific application. With proper installation and maintenance practices, these versatile components will ensure the smooth operation and long-term performance of your industrial ductwork system.