Refractory Materials

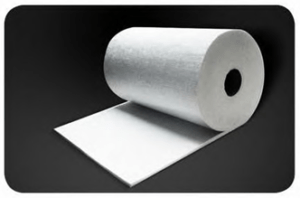

Biowool Blanket

Biowool blanket

is High strength, needled insulating blanket that is made from Biowool bulk. The combination of spinning and needling operation produces tough, resilient, and strong blankets. Which have superior thermal and mechanical properties. Biowool blanket is used in a wide range of applications including thermal insulation, appliances. The blanket can be folded, compressed, and encapsulated to produce modules. lt can meet European regulatory requirements (Directive 97/69/EC).

Features

- Excellent thermal shock resistance

- Excellent thermal stability

- High tensile strength

- Low thermal conductivity

- Low heat storage

Typical Applications

- Pipe wrap

- Furnace and kiln back-up insulation

- Annealing furnace linings

- Appliances insulation

- Expansion joint seals

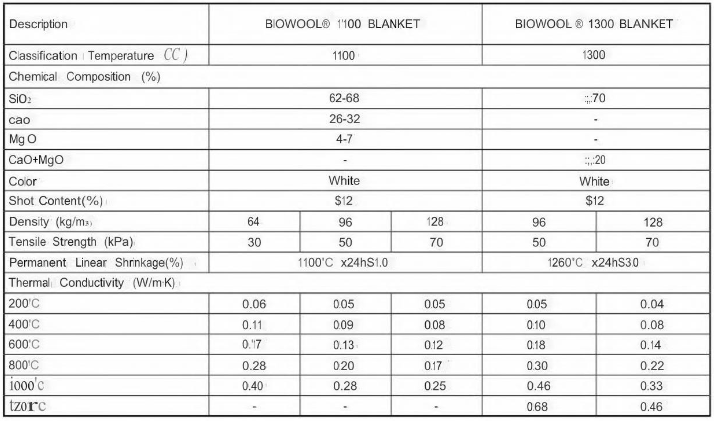

Typical Parameters

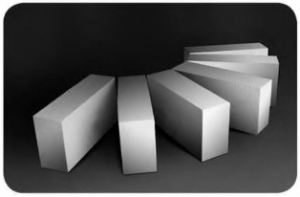

Brick

INSULATING FIREBRICK

Insulating Firebrick

is made from high-purity refractory powder and organic fillers which burn out during manufacture to give a uniform and controlled pore store. The brick is compressed in a vacuum and sintered under high temperatures. L Insulating Firebrick is widely used as hot face refractory lining or backup insulation in various kinds of industrial furnaces.

Features

-

Excellent thermal shock resistance

-

Accurate and customized dimension

-

High crushing strength

-

Low thermal conductivity

-

Low heat storage

Typical Applications

-

Metallurgy industry

-

Petrochemical industry

-

Ceramics industry

-

Aluminum industry

-

Glass industry

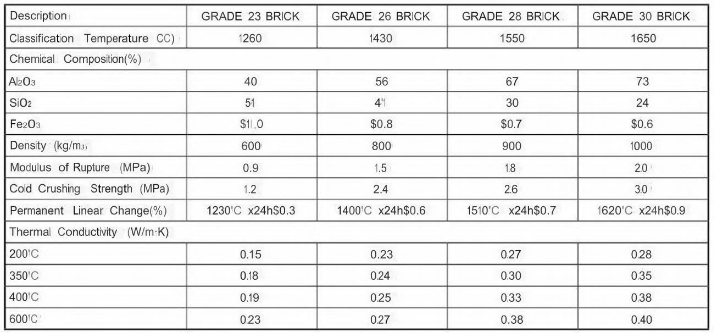

Typical Parameters

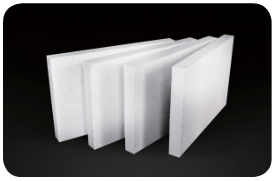

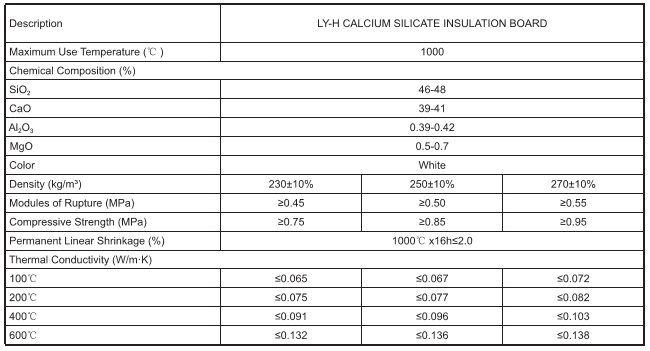

CALCIUM SILICATE INSULATION

LY-H CALCIUM SILICATE INSULATION BOARD

LY-H calcium silicate insulation board

is manufactured from xonotlite and reinforced fiber. It is entirely asbestos-free and non-poisonous to the human body. LY-H board is a kind of high efficiency and energy-saving product, with the maximum heat-resistant temperature up to 1000 ℃ .

LY-H calcium silicate insulation board

LY has characteristics such as excellent thermal stability, corrosion resistance and convenient construction, can be widely used in industrial furnace insulation.

Features

-

Excellent thermal stability

-

High rigidity and light weight

-

Can be machined,cut and shaped easily

-

Low thermal conductivity

-

Low heat storage

Typical Applications

- Cement,ceramic and glass

- Refining,iron and steel

- Non ferrous

- Petrochemical

- Power Plant

Typical Parameters

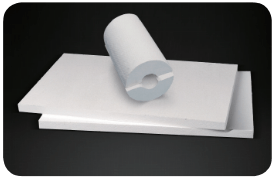

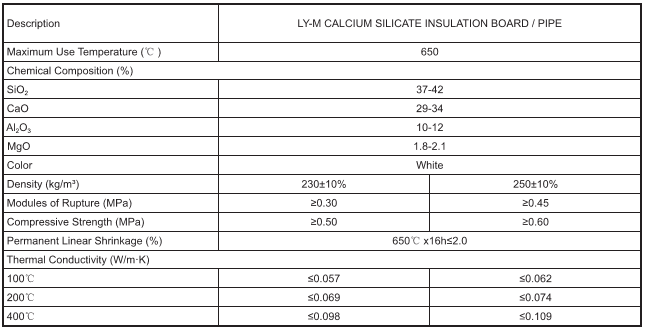

LY-M CALCIUM SILICATE INSULATION SERIES

LY-M calcium silicate insulation series

include board, pipe and other shaped product. LY-M calcium silicate insulation series is manufactured form tobermorite and reinforced fiber. LY-M series is a kind of high efficiency and energy-saving product, with the maximum heat-resistant temperature up to 650 ℃ .

LY-M calcium silicate insulation series

has characteristics such as Low thermal conductivity, high rigidity and convenient construction, can be widely used for insulation in industrial furnaces and thermal pipelines.

Features

-

Excellent thermal stability

-

High rigidity and light weight

-

Can be machined,cut and shaped easily

-

Low thermal conductivity

-

Low heat storage

Typical Applications

- Cement,ceramic and glass

- Refining,iron and steel

- Non ferrous

- Petrochemical

- Power Plant

Typical Parameters

“The data shown are typical average results of tests under standard procedures and are subject to variation. Results should not be used for specification purposes or creating any contractual obligation. For more information on the safety application or materials, please refer to the work practices and material safety data sheet.”

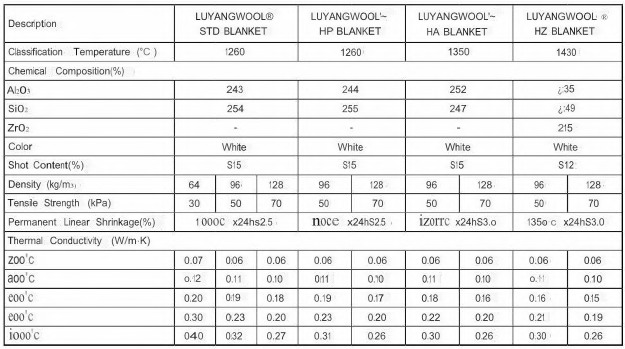

Ceramic Blanket

Blanket

is high strength, needled insulating blanket. The combination of long spun fibers and needling operation produce tough, resilient, and strong blankets. which resist earing both before and after heating. The blanket is completely inorganic and available in a variety of temperature grades, densities, and sizes. L blanket can be folded, compressed, and encapsulated to produce modules.

Features

-

Excellent thermal shock resistance

-

Excellent thermal stability

- High tensile strength

- Low thermal conductivity

- Low heat storage

Typical Applications

- Pipe wrap

- Furnace and kiln back-up insulation

- Chimeny insulation

- Annealing furnace linings

- Process heater linings

Typical Parameters

“The data shown are typical average results of tests under standard procedures and are subject to variation. Results should not be used for specification purposes or creating any contractual obligation. For more information on the safety application or materials, please refer to the work practices and material safety data sheet.”

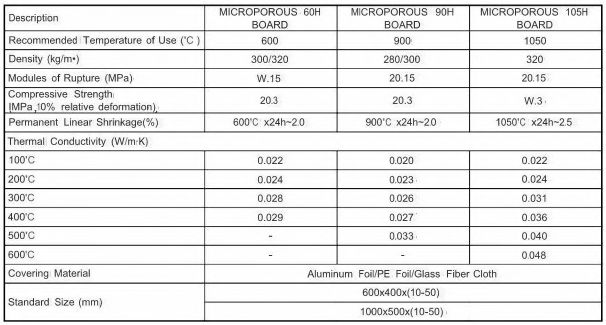

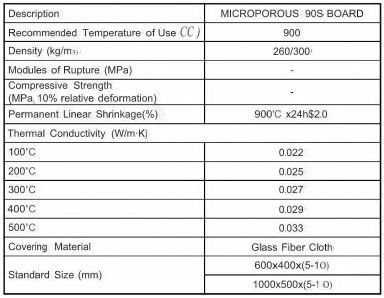

Microporous Hard Board

MICROPOROUS HARD BOARD

Microporous Board

is an efficient insulation product based on advanced microporous insulation technology. At low temperature, it has a lower thermal conductivity than still air. The thermal conductivity increases very little with the increase of temperature. At high temperature, its insulation effect is 3-4 times higher than traditional insulation materials.

Microporous H Board has high compressive strength, covered with aluminum foil or glass fiber cloth. lt is an excellent choice for the lightweight and energy-saving application of kiln.

Features

-

Excellent thermal shock resistance

-

Excellent thermal stability

-

Low thermal conductivity

-

Low heat storage

Typical Applications

-

Back-up insulation in high-temperature furnaces

-

Appliances insulation

-

Fire protection equipment

-

Electronic devices

Typical Parameters

“The data shown are typical average results of tests under standard procedures and are subject to variation. Results should not be used for specification purposes or creating any contractual obligation. For more information on the safety application or materials, please refer to the work practices and material safety data sheet.”

Microporous Soft Board

MICROPOROUS SOFT BOARD

Microporous S Board

is a flexible and efficient microporous insulation material formed by special process.lt is covered with glass fiber cloth. Microporous S Board can be used as insulation materials for various kinds of pipes and complex spaces.

Features

-

Good fit to curved surfaces

-

Low thermal conductivity

-

Low heat storage

-

Non-combustibility

Typical Applications

- Pipe insulation

- Fire protection

- Insulation for curved surfaces of high-temperature furnace walls and equipment

Typical Parameters

“The data shown are typical average results of tests under standard procedures and are subject to variation. Results should not be used for specification purposes or creating any contractual obligation. For more information on the safety application or materials, please refer to the work practices and material safety data sheet.”

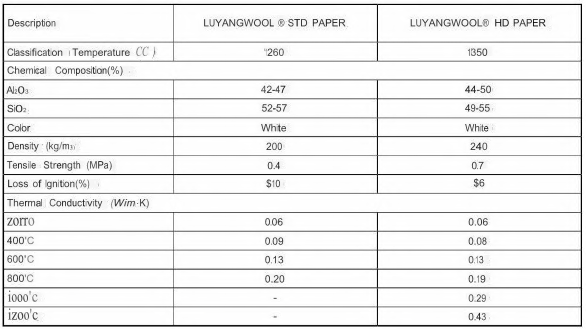

Paper

Paper

is manufactured by blending binders, and additives. The specialized paper- making process is used to form uniform and flexible paper paper is easy to be handled and cut. L paper can be used in a wide range of applications as thermal insulation. lt is especially suited to used in gaskets and as a parting medium.

Typical Parameters

“The data shown are typical average results of tests under standard procedures and are subject to variation. Results should not be used for specification purposes or creating any contractual obligation. For more information on the safety application or materials, please refer to the work practices and material safety data sheet.”

Features

-

Excellent thermal shock resistance

-

Can be machined,cut and shaped easily

-

High flexibility

-

Low thermal conductivity

-

Good dielectric strength

Typical Applications

-

Gaskets for high temperature applications

-

Gaskets for domestic appliances

-

Back-up lining for metal troughs

-

Thermal barriers for vehicles

-

Expansion joints